The days plan was to hit Davenport Ia. 40Th annual AMCA fall national which is a huge swapmeet and do all on back-roads. Jim was going all the way to the meet but would not head home with me but split off after and run up to Galena to meet his family. Tom was just out for a short ride and we pulled off at the site of Wild Bill's old home site.

Jim posing with Bill.

Tom making sure Bill's nose is clear. The man had a HUGE nose if this is close to scale.

Jim's never hit the Princeton covered bridge, so a stop was a must.

By this time the KLR was at 170 miles on the tank of gas so I checked the GPS. The next gas stop on my roughly planned route and it was 20 something miles away. Should be a fine distance and where reserve will just start to be needed. Besides a few towns were in between and might have gas stations not loaded in the GPS.

I couldn't remember if I topped off the tank the last fill up so 190 miles before reserve was in question while I enjoyed the open county roads. At around 185ish I had to flip the petcock and ride another 20 some miles to the GPS gas station. As we got closer to the shell station on the GPS is was clear there was nothing but a corn field. CRAP!!

Now I was panicking a little in my head and shot for the interstate but I couldn't imagine having another ten miles worth of gas left. It wasn't a BIG panic since Jim was with me and could shoot ahead and get a small can and run back.

Sure enough just before switching Interstates the bike quits. I hop off the bike and tell Jim I'm dry and I'm going to tilt the bike all the way over to the left and see if she fires up. Yep, she pops to life and I blast down the ramp to the ramp to I-80 and closer to more GPS gas stations but it's 8 miles away. Lucky for me a sign says a station is at the next exit just 4 miles away. As the bike hit the exit ramp she died again and I just pulled the clutch and rolled down to the intersection. Jim right behind me, I just said I'm tilting her over again and it worked.

I got to the gas station down the block and filled her up at 5.86 gallons and I just giggled. Never have I put that much in.

As we sat at the gas station drinking coffee and a gold wing club pulled up and they chatted with us.

The one big guy told us they were from the Peoria IL. area and we said the TT races were a favorite of ours. The big guy told us he was at the Indy mile race when Kenny Roberts took the TZ750 for it's big win. I would of killed to of seen it and this guy seemed like it was no big deal. Here's the link with a bit about it ---

Roberts.

At the swap meet surrounded by HD's and a few odd bikes.

Old Indian at the meet that he still uses for

vintage cannonball runs.

That little post-it note says 200K for this Flying Merkel.

Looking at this bike and trying to imagine my Grandfather hill climbing one of these, crazy..

This meet had some of the best old bikes I have ever seen. More Indians than I have ever seen in one place. The other odd thing was a lot of old Kawasaki bikes.

A little clip of a four cylinder Henderson, it didn't run longer than this clip.

This guy has it all, dog, girl and a bike..

when we came across these two Indian Chiefs I was in awe. They were perfectly clean and bright. I asked if they ever ride them and the man sitting down said yes.

I was stunned to see his young kids putting around on both of them. Must be great to learn the tank shifter and foot clutch deal. Also don't forget the throttles on the left hand and spark adjustment is on the right. I would really get wrong a few times, ok a lot! :)

If I remember it right this was a 1955 Ural. Looks just like the ones build up to the late 1990's.

Around a 1904 Indian

humpback or later with all it's mighty 2HP. I always wonder if any of my past or present bikes will make it this long.

Jim tailing and about to peel off just after this bridge picture.

This bridge ( just north of Savanna IL) is steel grate like most of the two lane bridges over the Mississippi. Look straight down and you see the river at the same time the tires are giving you a shimmy.

Stopping at a John Deer dealer to put the warm sleeves on since the weather was getting cooler.

The last issue I had for the day was my horn has been on the fritz. Hit the button and it may or not work. So, cruising down the road and no one around I blast it for a few seconds and bam it's off and I'm still on the button. I look at the GPS and it's off. Crap again, it blew the fuse but I know where I'm at but the speedo is more accurate than the bike.

Nothing like being my own problem..

Even with it all going a little wrong it was a nice full day of back-roads and great weather..

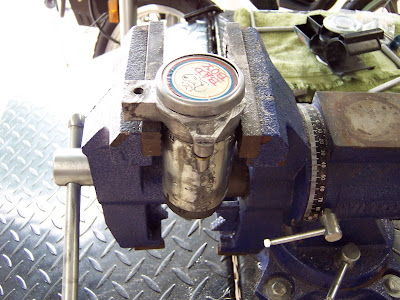

Pic's above is the new generation of balancer plates and a spring that's WAY too long and really is useless after 5K miles. The balancer plate is OK but the new billet plate fits on the adjuster shaft a lot tighter and knocks down a little noise.

Pic's above is the new generation of balancer plates and a spring that's WAY too long and really is useless after 5K miles. The balancer plate is OK but the new billet plate fits on the adjuster shaft a lot tighter and knocks down a little noise. Gen 1 or 2007 or older KLR's balancer system was a huge mess that Kawasaki never addressed for the 10 years of production. As you see above the weld has snapped on the plate above and if not found the balancer chain is left to come off and grenade the motor..

Gen 1 or 2007 or older KLR's balancer system was a huge mess that Kawasaki never addressed for the 10 years of production. As you see above the weld has snapped on the plate above and if not found the balancer chain is left to come off and grenade the motor.. Second issue is the spring ends were also know to vibrate off and leave zero tension on the chain when performing the manual adjustment. This spring was off a bike that the owner luckily never tried to manually adjust. Also the bike had under 5K and we never recovered the broken end of the spring. The spring end is know to sit at the pick-up screen for the oil pump and should never cause harm. I suggested a magnetic drain plug to the owner so if it still is floating around the plug will make it a home.

Second issue is the spring ends were also know to vibrate off and leave zero tension on the chain when performing the manual adjustment. This spring was off a bike that the owner luckily never tried to manually adjust. Also the bike had under 5K and we never recovered the broken end of the spring. The spring end is know to sit at the pick-up screen for the oil pump and should never cause harm. I suggested a magnetic drain plug to the owner so if it still is floating around the plug will make it a home.