The bad boy horn that was being bad blowing my fuse!

The bad boy horn that was being bad blowing my fuse! When I got a closer look with the right faring off I found the bracket I bought has cracked along the weld and at both mounting spots.

When I got a closer look with the right faring off I found the bracket I bought has cracked along the weld and at both mounting spots.

Second crack found and I'm not a happy camper.

Since the horn is dead we will see what went wrong. When I tested it on the bench it would lock up when voltage was hooked up properly but would run good when reversed. Hmmm....

Since the horn is dead we will see what went wrong. When I tested it on the bench it would lock up when voltage was hooked up properly but would run good when reversed. Hmmm.... I sawed off the top and my best guess that the vanes are catching at the inlet of the pump and stalling. If I was able to remove the top without destroying it I would of smoothed out the inlet ports so the vanes wouldn't snag and then retest it.

I sawed off the top and my best guess that the vanes are catching at the inlet of the pump and stalling. If I was able to remove the top without destroying it I would of smoothed out the inlet ports so the vanes wouldn't snag and then retest it. Little differences between the old and new horn is the screws holding the motor cap on and it doesn't say MADE IN ITALY any where on it. Now my bet is made in China.

Little differences between the old and new horn is the screws holding the motor cap on and it doesn't say MADE IN ITALY any where on it. Now my bet is made in China. While scoping out the web for a better bracket I found twistedthrottle sells one for this horn for about thirty bucks shipped and that would put this at a seventy dollar horn job. It's just a simple L-bracket painted black and no way I'm paying for that.

While scoping out the web for a better bracket I found twistedthrottle sells one for this horn for about thirty bucks shipped and that would put this at a seventy dollar horn job. It's just a simple L-bracket painted black and no way I'm paying for that.A little trip to the hardware store for some metal and time to get to work on my own bracket for cheap. The strip of metal cost me two dollars and is one inch wide by three feet long. For the paint I'll use some old black that's been laying around in the garage..

I could of just left the ends square but I had some time to smooth them out and look like a little love went into it..

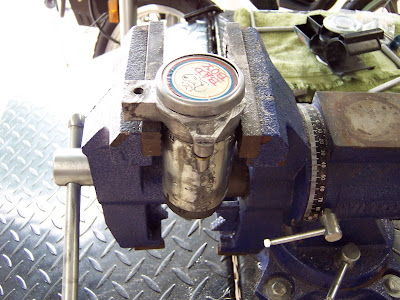

I could of just left the ends square but I had some time to smooth them out and look like a little love went into it.. I stuck about a inch and a quarter into the vice and hammered it over to ninety degrees.

I stuck about a inch and a quarter into the vice and hammered it over to ninety degrees.

Nice and square.

Nice and square. I checked out about where it would need to

I checked out about where it would need to length was about 4"3/8.

length was about 4"3/8. mounting tang 1"1/4.

mounting tang 1"1/4. primer and painted.

primer and painted. Mounted and looking like something out a the road warrior.

Mounted and looking like something out a the road warrior. Horn on and looking good!!

Horn on and looking good!! And here is where self-engineering hit's a little snag. Contact with the fairing like this will cause the plastic to crack eventually.

And here is where self-engineering hit's a little snag. Contact with the fairing like this will cause the plastic to crack eventually. Top shot and you can see the horn bowing the fairing out a little.

Top shot and you can see the horn bowing the fairing out a little. Even with the horn tilted back like this the whole body of the horn was contacting the fairing. The gap between my fingers will almost be how much I'll shorten the length of the bracket.

Even with the horn tilted back like this the whole body of the horn was contacting the fairing. The gap between my fingers will almost be how much I'll shorten the length of the bracket. The new length is now 3"5/8 and time for some more paint.

The new length is now 3"5/8 and time for some more paint. Shortened and tilted back with a little bit of clearance from the coolant reservoir cover.

Shortened and tilted back with a little bit of clearance from the coolant reservoir cover. The garage company. :)

The garage company. :) Done and looking like a pretty clean job. I'm really hoping the bracket and horn will survive longer than a year and a half. Being that it's mounted only one one bolt it's going to vibrate a lot, so time will tell.

Done and looking like a pretty clean job. I'm really hoping the bracket and horn will survive longer than a year and a half. Being that it's mounted only one one bolt it's going to vibrate a lot, so time will tell.

5 comments:

Isn't it satisfying to do your own mods and save money in the process? And what lovely garage company you have! Great stuff.

Man, this brings up the farkle memories... It just ain't a homemade bracket until you have to cut a few inches off the end of your first try. Or maybe I just suck at measuring.

I've been meaning to ditch my asthmatic duck for a real horn, but have never gotten around to it.

Nice write up on the horn install, and +1 on the custom bracket. A better horn is on my to-do list (well, Ron's to-do list) one of these days.

Replacing my factory horn with a Bad Boy horn is something I want to do quickly. You got to have a good horn to wake up the cagers.

This blog is very good and efficient with what it does. You give detailed explanations on your posts which make people to understand so much about this topic.

Post a Comment